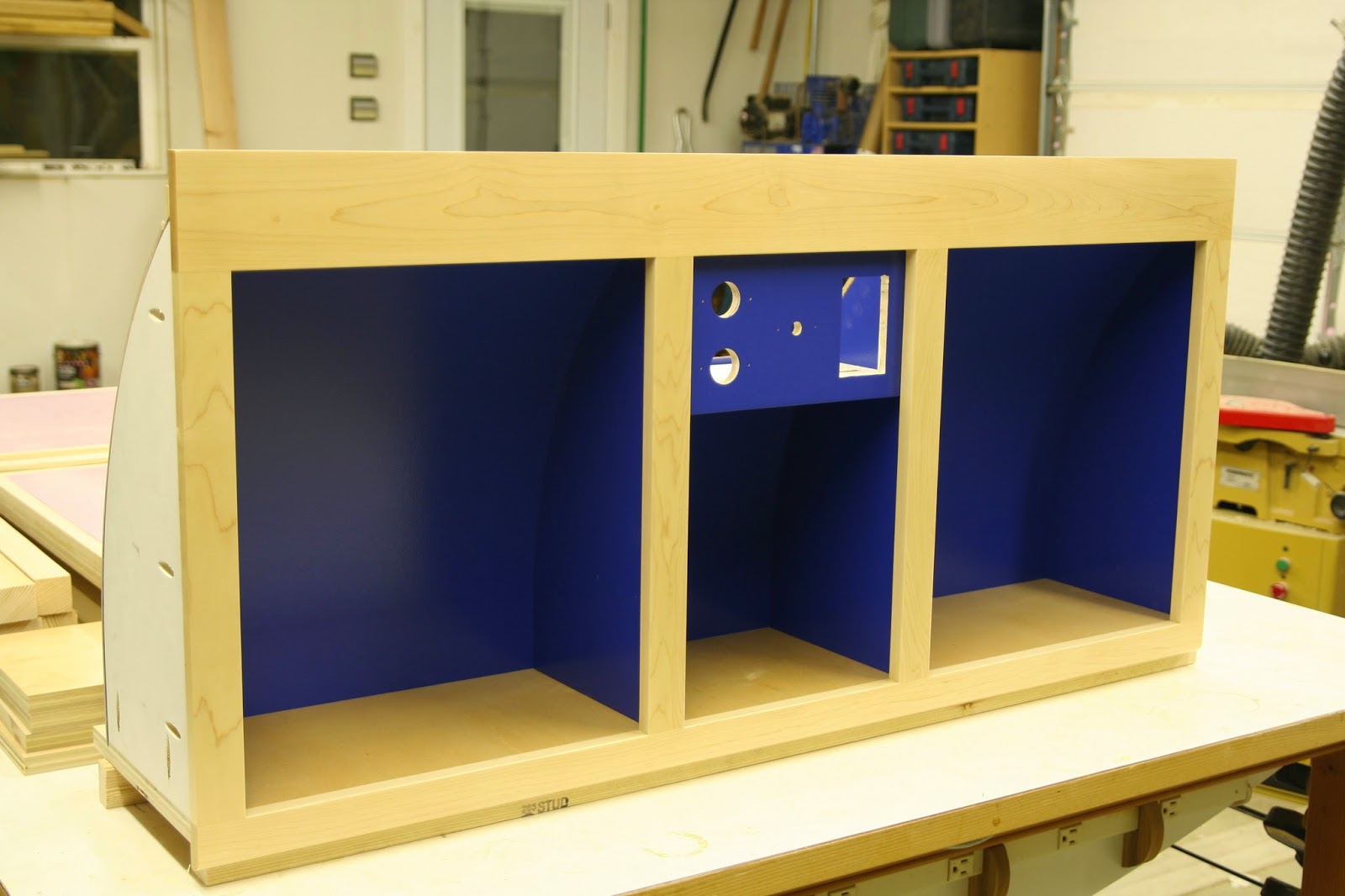

Here is the assembled cabinet. The cabinet back follows the curve of the front of the camper's roof. Eventually there will be doors flanking the open cubby in the center. The upper section of the cubby will have a reading light, two 12v outlets, and a 120v outlet. This cabinet will sit on top of the front bulkhead.

Spoiler alert! Don't look at the background of this picture! I had to dry fit the camper (assemble with no glue and few fasteners) in order to work out the exact dimensions of some parts, particularly the height and angle of this cabinet's profile. I may have mentioned before how much I love the finishing process. Because I love it so much and feel it is immoral to indulge in too much guilty pleasure, I use pre-finished maple plywood here and wherever possible.

This is the aft (over foot) cabin cabinet. It will share a back with the upper galley cabinet. If you refer back to the first picture, you can see (hidden by the forward bulkhead, the galley countertop with a dark gray plastic laminate. It's hard to see, but attached to it's back edge is a vertical piece of plywood. That plywood will serve as the back for this cabinet, for the galley upper cabinet, and as the pivot point for the galley hatch. Now that my basic components are finished and assembled, I am almost ready to start putting this thing together. There are still a couple of things to do to get the trailer prepped.

|

| This rubber seal will keep water out of the area of the camper side that will be covered by the wheel well |

|

| The cabin flooring has been installed prior to assembly. |

As we all are getting ready to stuff as much food as possible down our throats and lay around with friends and family in a tryptophan induced stupor watching one football game bleed into the next, I'd like to briefly remember the Thanksgivings of my youth. How could this possibly be relevant? Bear with me and I'll try to explain what is, for me, more than a marginal relevance. My earliest Thanksgiving memories are of Nanny and Papa's warm and happy home in Gainesville, FL. My grandmother would cook an amazing quantity and variety of food in a kitchen that couldn't have been more than 10'x12'. How she did it, I'll never know, but in my recollection, it was effortless and the food was always pure southern perfection.

When dinner was winding down and I'd had enough of sitting around the table, I would inevitably find my way to my favorite part of that house; the garage where Papa kept his shop. He had this wall of tools and gadgets and fasteners and things that I had no idea what they were, and I would just stand there messing with his stuff, trying to figure out what the things did. If ever I asked him, he would stop whatever he was doing to tell me. When he was explaining things he used the word "kindly" to mean "sort of" or "like". I've never heard anyone before or since use that word like that. He always had a box of scraps and a can of nails that he would let me bang away at. I spent a lot of time nailing random boards together on the garage floor.

This was the place and he was the man that sparked in me the desire to make things. I always loved it when I saw him get his toolbox because I knew it meant that I would get to "help" him fix or build something. I was very fortunate to have known his gentleness, patience, and creativity. It is something that I give thanks for every Thanksgiving, and in fact, much more often than that. If it weren't for Papa who knows if I'd have built a treehouse or if I'd be building a camper now? Thank you Nanny and Papa, and Happy Thanksgiving everyone.